MES - Software solutions for maximum efficiency in production

A Manufacturing Execution System (MES) is a specialized system that supports manufacturing processes. These solutions have a much higher degree of specialization in the planning, controlling, and tracking of production then the more well-known ERP solutions. These MES solutions can create the value that is needed to reach the goals of the organization.

The shop floor planning capabilities are often needed in complex manufacturing situations. MES solutions are often needed where the requirements concerning quality or efficiency are especially high. Another business case for MES is when real-time shop floor data is needed to optimize production or when measurement data is needed to document and validate production steps. Data collection and documentation usually takes place automatically through the interface between the production machines and the MES software. MES enables the “Internet of Things”.

Our services in the area of MES

A Manufacturing Execution System (MES) is a specialized system that supports manufacturing processes. These solutions have a much higher degree of specialization in the planning, controlling, and tracking of production then the more well-known ERP solutions. These MES solutions can create the value that is needed to reach the goals of the organization.

The shop floor planning capabilities are often needed in complex manufacturing situations. MES solutions are often needed where the requirements concerning quality or efficiency are especially high. Another business case for MES is when real-time shop floor data is needed to optimize production or when measurement data is needed to document and validate production steps. Data collection and documentation usually takes place automatically through the interface between the production machines and the MES software. MES enables the “Internet of Things”.

MES Evaluation

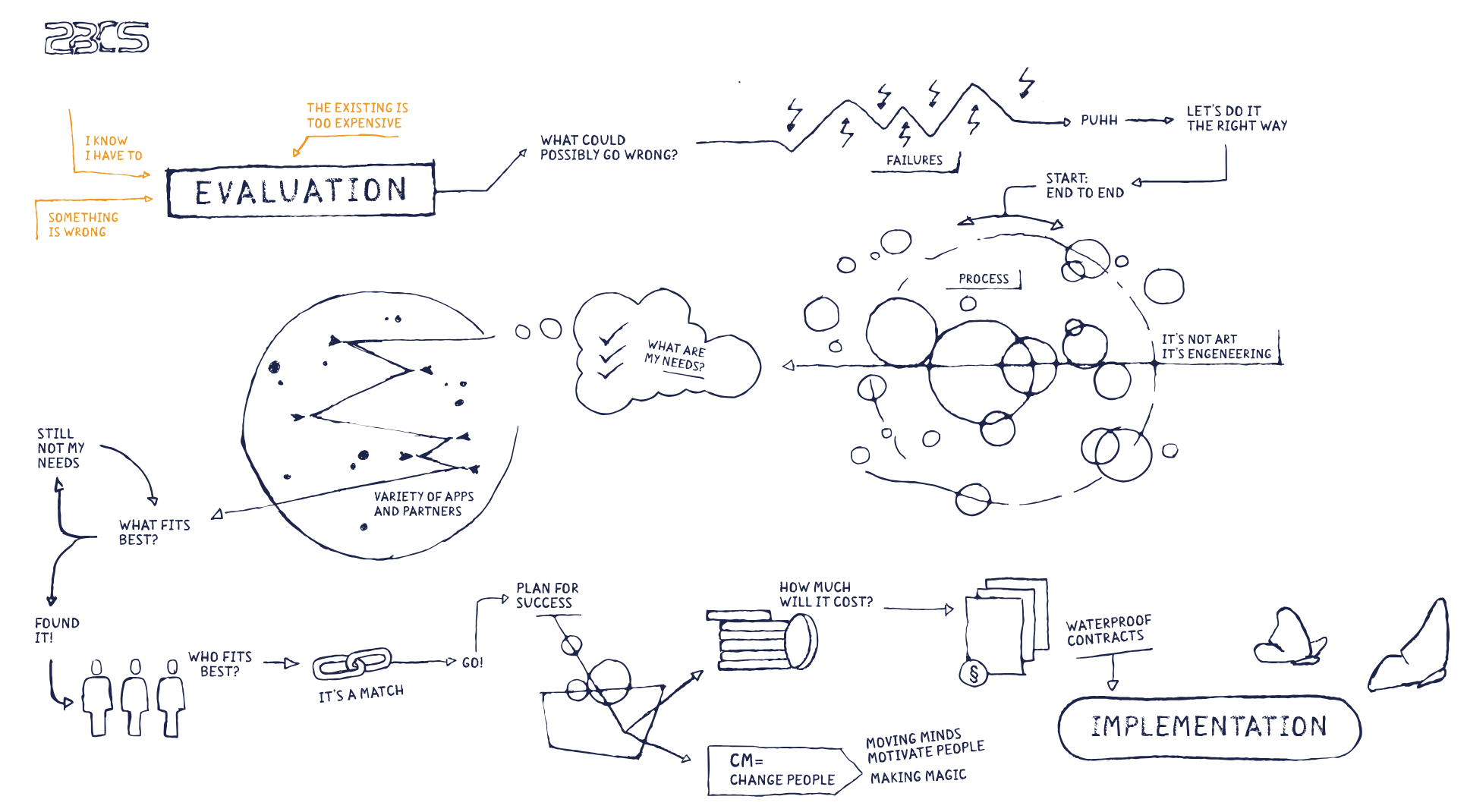

MES solutions cover a wide range of functionality. In a first step we will scope the topics. The relevant topics and processes will be detailed in workshops and the requirements will be defined. These requirements are the foundation of the MES evaluation and the search for the right partner. The solution and partner will be identified in workshops and a waterproof contact covering functional and financial issues will be negotiated by 2BCS.

MES implementation

Implementing MES solutions means clearly having a picture of the envisioned benefits and striving for these. At the same time, it is vital to understand that an MES implementation is complex and expense. There are also risks associated with such a project. Our experience shows that in most cases our clients hardly have the resources, know-how and experience to manage such an MES project. 2BCS gladly supports clients when implementing their MES solutions. Three different support options are available. Each option has a different scope and associated effort:

- A 2BCS consultant takes over the role of the Project Manager. We will ensure a successful implementation from A to Z.

- Coaching expert. We will support the Project Manager with our implementation expertise in the areas of risk management, testing, training, quality assurance, roles & permissions or change management. A coaching of the Project Manager is also an interesting option.

- Active participation in the Steering Committee of the MES implementation. We will make sure that our clients’ interests are adhered too and the strategic decisions are taken.

Our customer promise

2BCS clients profit from our know-how concerning production and shop floor processes, our profound MES experience and knowhow. Our expert’s advice you independently of any interests and with many years of experience evaluating MES systems and carrying out negotiations to the benefit of your organization. After contract signing, we can ensure that the implementation is carried out in an efficient, best practice manner. This promise is based on our methods, our understanding of quality and the consultants proven experience in implementing MES and ERP solutions in manufacturing organizations.

Contact form

Use the contact form if you have any questions about our products. Our team will be happy to help you!

Book an appointment

You can also make an appointment with us for a Microsoft Teams meeting instead of using the form. Please use the link below.

Arrange an online meeting now